|

PORTABLE ECO GENERATOR

ABOUT - CLIMATE CHANGE - CONTACTS - CROWDFUNDING - DONATE - FOUNDATION - OCEAN CLEANUP - SEAVAX - HOME - A-Z INDEX ARRAYS - BOOM - MASTS - INTERIOR - PAINTING - ROBOTICS - WELDING - WIND TURBINES

ROOF RACK - Less then three months after design began, the base frame is bolted to a Ford Transit donor vehicle. Copyright © photograph 12 May 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

We are, in effect, creating a portable solar and wind electricity generator. Although this is an experiment for our coastal development rig, the vehicle would make an excellent green power supply for eco events, third world villages and isolated country locations. That is another way of helping to slow global warming.

It looks simple, but for every experiment like this there is a lot of hidden engineering and problem solving. On this page we look at the masts in more detail, such as the brackets and pins, all of which involves machining, drilling and cutting operations that add up and take time to complete.

DEEP END - More hydraulic pads for the rams to push against, this time for the inside of the vehicle. Copyright © photographs May 25 2019. All rights reserved, Cleaner Ocean Foundation Ltd.

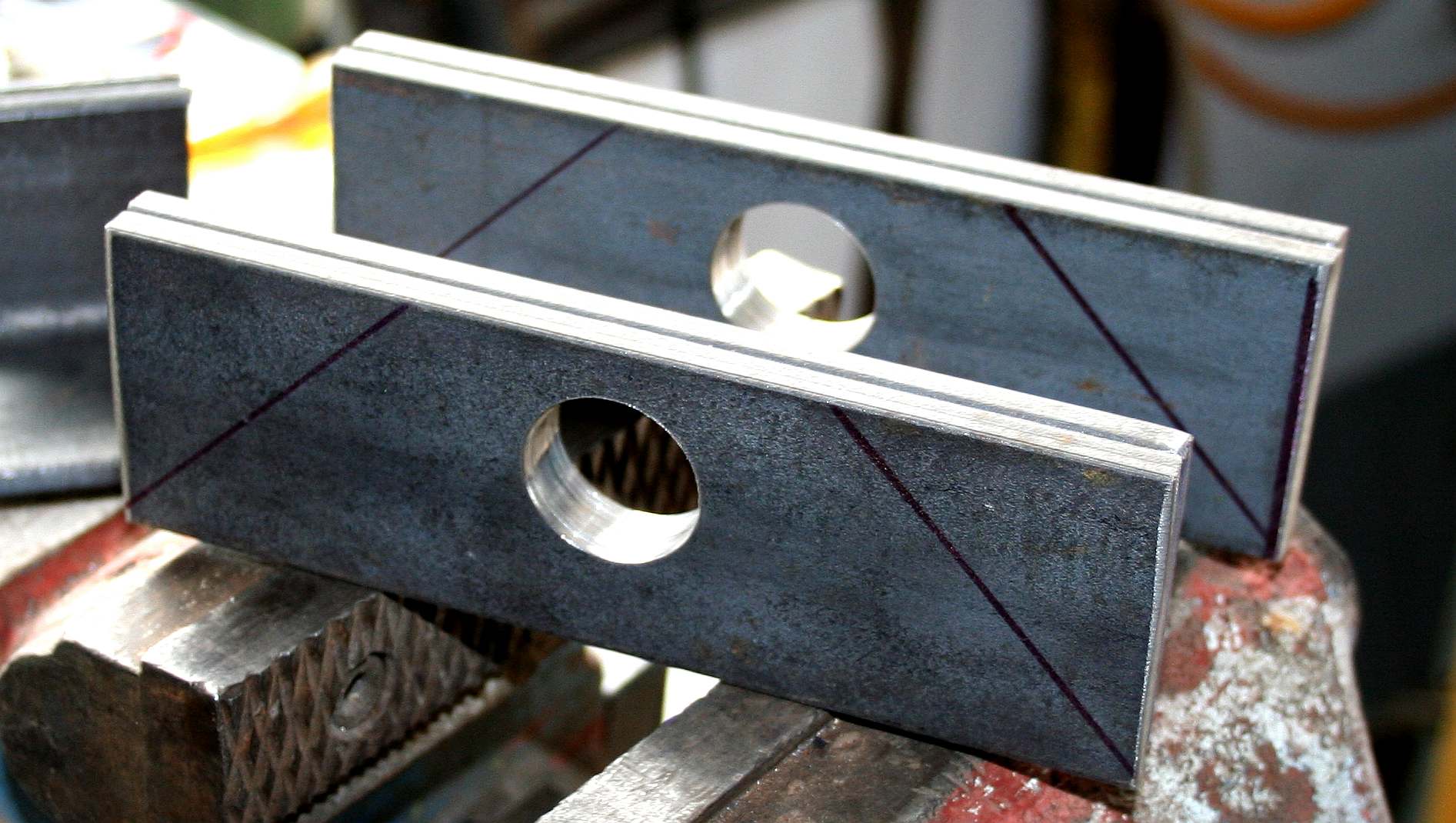

PADS - These are four steel banks drilled to 25mm to match the ends of the mast lifting hydraulic rams. They will be welded to a base that is wider than the mast frames to accommodate the hydraulic ram ends. Copyright © photograph 27 May 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

MARKING OUT - Chris drills pilot holes for the parallel links between masts. Copyright © photograph 26 May 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

PIN LINKS - Higher up the mast frames we needed two 12mm steel pins for tension sharing links between the mast frames. They had to be welded in place so as not to weaken the frames at a crucial loading point. Copyright © photograph 29 May 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

PADS - Finally the pads for the hydraulic pins are welded in place. At the top-left of this picture you can see a reinforcing plate that is welded to either side of the lower mast frames for load sharing compression links between upper and lower mast frames. These moveable links connects both masts to transfer lifting loads as evenly as practical. Copyright © photograph 29 May 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

RED OXIDE - The lower mast in red-oxide primer, complete with pins, pads and reinforcing gussets. Steel in prone to rust easily in a marine environment no matter how good your painting preparations. For this reason SeaVax is to be built of 5083 alloy. Copyright © photograph 29 May 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

DESIGN LAYOUT - These are the working drawings for the conversion to a portable eco generator. The steel roof frame sits on top of plywood pads to act as soft seat buffer. Inside the van we need to make a steel frame to take the loads of two hydraulic rams that will go through the roof, to lift the mast. We'll worry about waterproofing the opening later. Copyright © diagrams March 12 2019. All rights reserved, Cleaner Ocean Foundation Ltd.

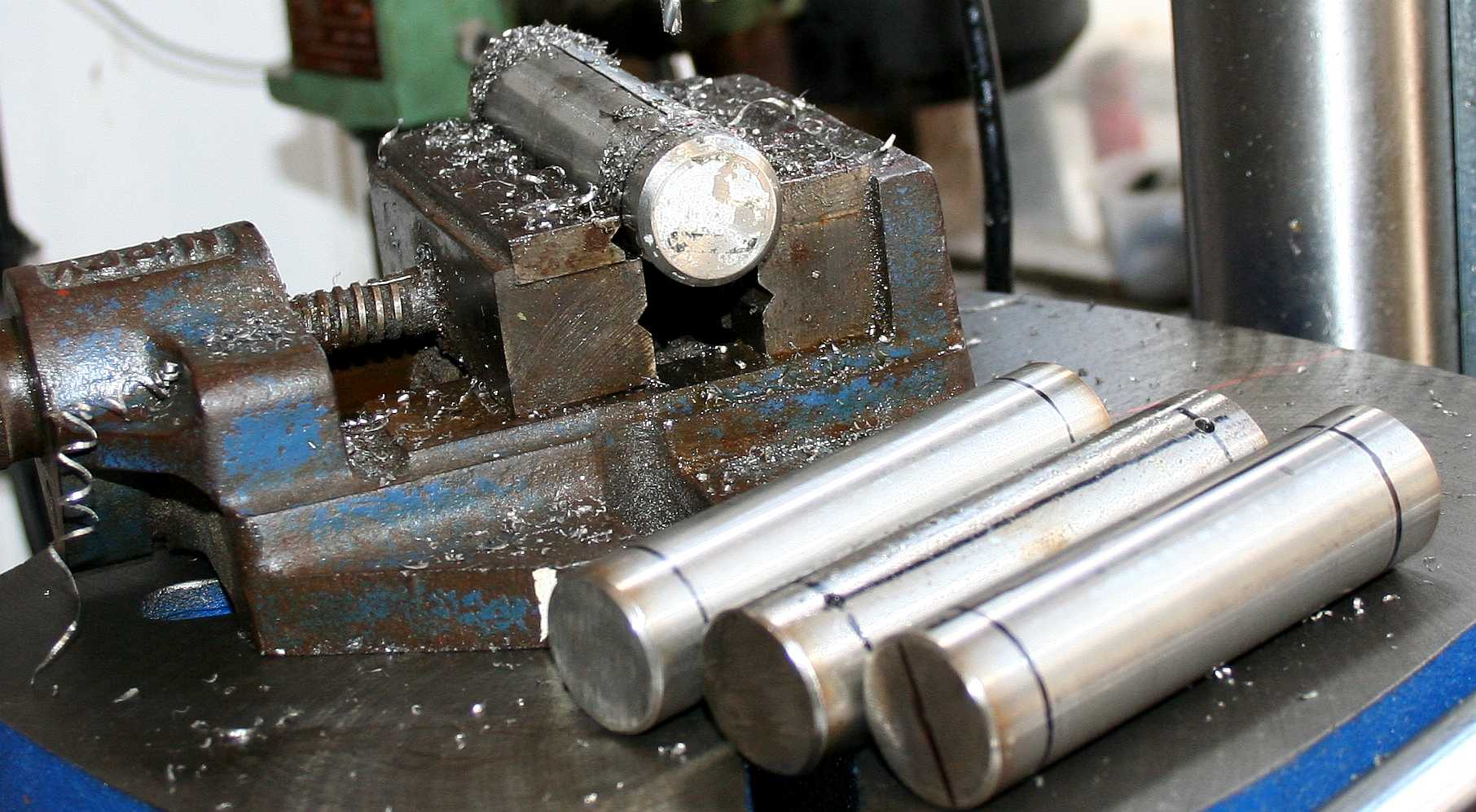

STEEL PINS - Drilling the steel pins for the mast hinges is a three stage operation where the pin cannot be moved from the portable vice until the correct hole size is achieved, using plenty of cutting fluid. Copyright © photograph 6 June 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

ALMOST THERE - With the holes drilled we need to chamfer the ends to match, though this is cosmetic where the burrs have been removed. Copyright © photograph 6 June 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

PANEL BEATING - Not for the faint hearted. Marking and cutting slots in the roof of the Transit van leaves little room for error. Our lead fabricator has panel beating experience from customizing cars. In this case we needed to cut through one of the pressed steel beams supporting the roof, also a seam. Suitable reinforcing and drainage gullies will be added once the opening has confirmed clearances for the hydraulics rams. Copyright © photograph 6 June 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

SEEING THE LIGHT - No turning back now. This is a view from inside the Ford Transit. We need to complete this phase and waterproof the openings with flexible rubber sheeting. There is a drip tray below to catch any dribbles during development. Copyright © photograph 6 June 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

RAM SLOTS - Two hydraulic rams protrude through these openings to link with the pads on the underside of the lower mast frame. Copyright © photograph 6 June 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

SUB

SAHARAN AFRICA - One

of the major barriers to electrification of Sub Saharan Africa

is the cost of a grid connection. A grid connection in Kenya,

for instance, is estimated at USD$ 400 per household. This is

nearly one-third of the average per capita income of a Kenyan.

Take the example of the Kenya Power and Lighting Company, which owns and operates most of the electricity transmission and distribution system. In 2015 it introduced a subsidized connection fee of US $150. This was done through the Last Mile Connectivity Project. In one year, this installment-based payment plan led to a 30-fold increase in legal electricity connections in impoverished neighborhoods. But the project was marred by cost overruns and inflated and misreported new connection numbers. On top of this, newly connected households often have very low consumption levels and low-income customers were often unable to make payments, even at subsidized rates.

Without the necessary infrastructure development, experts argue that the program puts a strain on the technical, commercial and financial resources of the utility. This means that the programme may find it difficult to generate revenue, recover costs or provide the service intended to new customers.

Africa is Earth's oldest and most stable landmass, with most of the continent having been where it is now for more than 550 million years. Most of it is a vast plateau, with only ten percent of its land area below an altitude of 500 feet. Near the equator are humid rainforests, but north and south of that band, most of sub-Saharan Africa is savanna, grasslands with scattered trees.

Lest we forget, the reason for doing this experiment is to see how much power we can generate for ocean and river cleaning machines with computer controlled wind and solar energy tracking.

WELDING - Our TIG, MIG and plasma cutting equipment was supplied by: R-Tech Welding Equipment Ltd Unit G1 & G2 Innsworth Technology Park, Innsworth Lane Gloucester UK. GL3 1DL. Tel: 01452 733933

LINKS & REFERENCE

https://www.gembloux.uliege.be/ https://www.picross-eng.com/ https://www.parkersteel.co.uk/ https://www.r-techwelding.co.uk/ https://web.stanford.edu/group/efmh/winds/global_winds.html https://www.quora.com/Why-does-winds-velocity-increase-when-height-increases

THIS IS WHY WE CARE - This humpback whale is one example of a magnificent animal that is at the mercy of human activity. Humans are for the most part unaware of the harm their fast-lane lifestyles are causing. We aim to change that by doing all we can to promote ocean literacy to help reduce our plastic, food and carbon footprints.

ARRAYS - BOOM - MASTS - INTERIOR - PAINTING - ROBOTICS - WELDING - WIND TURBINES

This website is provided on a free basis as a public information service. Copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2019. Solar Studios, BN271RF, United Kingdom. COFL is a charity without share capital. The names Amphimaxô RiverVaxô and SeaVaxô are trademarks.

|