|

STEM - CHARGING STATION NATIONAL GRID FOR EVS

ABOUT - CONTACTS - FOUNDATION - HOME - A-Z INDEX

EV INFRASTRUCTURE PROJECT - What lays ahead for drivers in the UK once petrol cars are no longer allowed to be sold after 2040. That happy situation for environmentalists is more of a challenge to managers of the National Grid, not too mention local authorities who need to think hard and plan ahead for our low carbon future - and that may not be electric vehicles - but they are the front runners at the moment. Hence this STEM project proposal to build a 1/20th scale proof of concept model of an EV service station to cater both for trucks and cars.

This station eliminates the need for fast charge waiting and does not reduce the battery life with such rapid energy exchange demands. A typical exchange cycle is just minutes using batteries in convenient packages called cartridges. The mechanical handling system in this unit can store 96 cartridges, all being sequentially charged ready for the next customer.

The Cleaner Ocean Foundation can dedicate four-six weeks of mentor time to this project - aiming for completion of this stage in the making of a Proof Of Concept model in four weeks. You will have the services of a model maker and welder/fabricator to assist, and a stock of materials and parts, including Arduino and Raspberry Pi computers (depending on your preference) to control the battery supply sequencing. Being AutoCad literate will help, but we can print large scale drawings if you prefer to work from paper for example for the construction of the shell of the building. 3D plastic printing may be used to produce some of the mechanical internal parts, though we would prefer it if these were made from stock robot making components that are available off the shelf. In 1/20th scale this is possible.

PROBLEM: The United Kingdom is to cease production and sales of petrol powered cars by 2040 in line with the targets imposed by the Climate Change Act 2008. The plan to phase out polluting vehicles may only be achieved if there is an energy supply network in place to enable the UK fleet of some 25,000,000 million vehicles to recharge batteries, or otherwise supply other forms of clean energy for motorists.

EV motoring is already a practical proposition for many drivers. We operate a BMW i3. Hence, we will use this vehicle as a baseline for many of our calculations because this is solid information that is already widely published.

At the moment (Feb 2018) there are roughly 14,000 charging points in the UK. If we were to provide 25 million charge points to enable on street charging for everyone, we would have to install around 700 charging points a day for the next 20 years. Clearly, that is a daunting task and such provision offers no buffer for electricity generators - when much of the electricity the UK produces is made overnight and where real time driving means recharging during the day on longer journeys. Especially, for heavy haulage and light goods deliveries from Amazon, Ebay and even supermarket grocery deliveries for those who shop online.

That is the beauty of petrol and diesel fuels. The energy in fossil fuels is stored in a convenient form for virtually instant transfer from the petrol station to the vehicle that needs fuel using a pump. Fuels are transported by road in tanker trucks and pumped from the tankers to underground storage tanks, that is then pumped on demand into the fuel tank of the motor vehicle being serviced.

The system may be cumbersome where there are no supply lines as with water, such that delivery by trucks may be taken out of the equation. But, apart from this and the risk of fire or explosions from flammable fuels - the system is superb except for the fact that fossil fuels are a non-renewable resource and for the air pollution they cause - that is one of the main causes of climate change. Air pollution also causes acid oceans, and that is where we come in.

DISRUPTIVE TECHNOLOGY

The Cleaner Ocean Foundation believes that the technology exists today that only needs to be modified, to be able to provide a network of energy charging stations at strategic locations in the UK to satisfy the charging requirements of up to 25 million vehicles.

The possible solution - no doubt one of many - is laid down here at a basic theoretical level ignoring transmission and charging losses. If you'd like to know more about the National Grid we have set out some information on the subject, though based on 2005 figures.

WHAT IS THE IDEA?

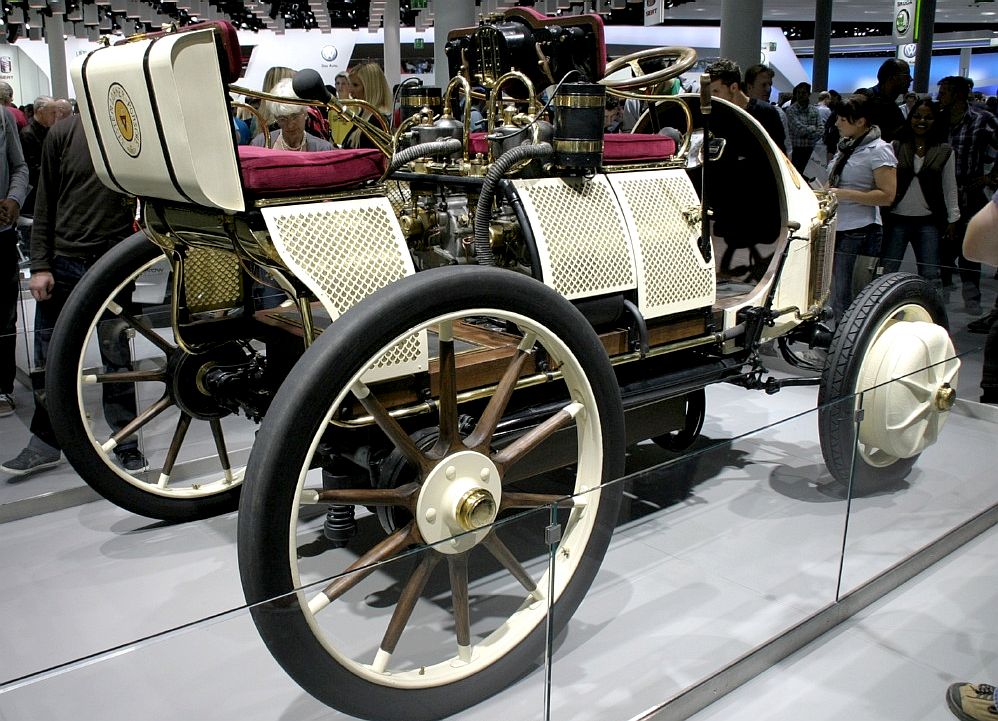

It's not really a new idea, but the way the old idea it adapted is new. Most electric vehicles today have a battery box or tray, such as the Tesla S. But did you know the Professor Ferdinand Porsche was using battery cartridges for his cars as early as 1900, and he was using power lifting equipment to carry out fast cartridge type exchanges to recharge his Lohner EVs?

The only difference is that with our system we are using modern handling equipment and marrying that to a continuous feed cartridge delivery system.

WHAT ARE THE DRAWBACKS?

Even if we show that the idea is solid, backed up by solid calculations and energy requirement assumptions based on past figures from the Grid, whoever champions such a system would have to persuade the motor manufacturers and truck makers to agree a basic format for the boxes that we call cartridges in this proposal.

In the competitive world of car sales, most vehicle producers are likely to want to press ahead with their own system. The only way to entice manufacturers in. would be if the energy supply companies liked the load-leveling feature of this system enough to want to back the concept.

Another way forward would be for the Government to create statute to support and require agreement and signing up to a form of cooperation in the interests of National and Energy Security. These being the options, the STEM students might want to consider lobbying the appropriate MPs for feedback, as part of this project.

NATIONAL GRID - Starting with the AutoCAD drawings of the proposed EV service station, you will construct a working scale model of a sequential battery cartridge charging system that is housed within the height and (plan) footprint of the diagrams provided. The inner workings of the system are not shown here for legal reasons, where a patent application is due to be filed. Once filed, the team can reveal the workings to the world but not before. If there are any legally minded students they get to see how to file a patent as a bonus.

1. In the first week you (your team) will conduct a survey of current production vehicles, vans and trucks and agree a suitable volume and dimensions for a cartridge format that is likely to be acceptable to the majority of vehicle producers. The volume will be calculated on the energy density of current Lithium based batteries.

2. In the second week you will set (mark) out a base board and fix the sequential handling machinery in place to be assembled Meccano fashion from as many stock parts as practical. You will then make 48 dummy battery cartridges out of foam blocks and affix pickup handles.

3. In the third week you will begin programming the Arduino or Raspberry computers to deliver (drop) one cartridge onto a delivery conveyor - so that the cartridge is placed in the correct position for the next vehicle pickup. You will be using stepper motors like those used in larger printers as the motive power.

4. In week four you will make and fit the building walls and roof and suitably treat and paint the completed unit. Programming can continue while the model building is being painted.

5. If you would care to attend a fifth week you will run the recharging sequence, film and document the project by way of a short presentation about the possibilities of such a system

6. A sixth week might be used to refine and perfect all of the above and decide who might like to see your work.

We will purchase all parts and materials in advance and host the project and provide meals and drinks during breaks. The above schedule of works is suggested. The student(s) will decide for themselves on the logical order of development.

If you choose to accept this mission for 2019 contact STEM Sussex and the coordinators will make the appropriate enquiries for you. The Cleaner Ocean Foundation can operate only two of these project in any one year due to staffing and facility limitations. For this reason students and coordinators are urged to state their interest as early as possible to start late 2018 or at some point in time in 2019.

COF LTD STEM PROJECTS:

ABOUT STEM - BOAT HULL LOW CARBON DESIGN - ELECTRIC SPORTS CAR GULL WING DESIGN

UK MAP - Draft infrastructure networked grid for the UK to kick-start EV service station building, aiming for a low carbon society that is sustainable and climate friendly by 2050 to comply with the targets set by the Climate Change Act 2008. This map is simplified and includes the Republic of Ireland for practical reasons. If we use just the intersections as likely locations that would mean installing 60+ stations, that could recharge more than the 14,000 charge points in the UK as of January of 2018. Another 1,800 such stations at strategic locations could service all 25,000,000 million vehicles in the United Kingdom. Optimistic, but you have to start somewhere when conceptualizing.

SMART SERVICE STATIONS - Seen above is a concept 7.68 - 15.36MW solar assisted service station containing 48-96 cartridges on a continuous charge cycle. Five of these stations (76.8MW) could recharge (refuel) up to 10 trucks or cars a minute at peak times. Next time you visit your Amoco, Chevron, BP Shell, Texaco or Supermarket fuel pump, count the number of cars leaving the station in a minute. You will find that an electric forecourt holds the potential to be quicker.

During rush hour, up to 300 vehicles might be serviced in one hour if drivers don't dawdle, as in get out of their vehicles - there is no need using automated billing - but this would require registered users. The truck shown here is 3.55 wide x 3.5 high x 7.7M long (8 x 11.5 x 25 feet). This station could accommodate trucks 4.46M (14.77 feet) high as shown, or with a raised roof, almost any truck currently on the market - though longer thinner trucks are more fuel efficient.

During an eight hour day 2,400 trucks might be serviced using five forecourts on the assumption that we start every morning with 96 x 5 = 480 slow charged cartridges from off-peak supplies. The same forecourt might be used to service fuel-cell cars powered by stabilized hydrogen. One size fits all. The secret is to KISS the design (Keep It Simple Silly). There are only 28* moving parts in this station, not including the gearbox for the solar powered drive motor. This is possible because with this system the vehicles load the cartridges themselves. Learn more about this concept.

THE NATIONAL GRID

The National Grid is the high-voltage electric power transmission network in Great Britain, connecting power stations and major substations and ensuring that electricity generated anywhere in England, Scotland and Wales can be used to satisfy demand

anywhere else in the country.

In Scotland the grid split into two separate entities, one for southern and central Scotland and the other for northern Scotland, connected by interconnectors to each other. The first is owned and maintained by SP Energy Networks, a subsidiary of Scottish Power, and the other by SSE. However, National Grid plc remains the System Operator for the whole UK Grid.

Mains electricity comes in to our homes at a voltage of 230 Volts (V). However it is not generated at 230 volts because the current in amps (A) needed to push the energy through extremely large cables would be huge. Big currents need thick cables that get hot. In our power stations electricity is generated at 25,000 volts (at a current of 100,000 amps).

Outside power stations there are huge step-up transformers that take the voltage from 25,000 volts to 275,000 volts (Kv). The voltage can be as high as 415,000 volts in the super grid.

It was Nikola Tesla who established the principles of three-phase high-voltage electric power distribution while he was working for Westinghouse in the United States in the early 19th Century.

TRANSFORMERS

The transformer is a vital part of the National Grid

in terms of limiting energy losses.

UK NETWORK SIZE - FROM 2005 SEVEN YEAR STATEMENT

Maximum demand (2005/6): 63 GW (approx.) (81.39% of capacity)

LOSSES - FROM 2005 SEVEN YEAR STATEMENT

Joule heating in cables: 857.8 MW

USEFUL FIGURES

Power = current (A) × Voltage (V) In Physics Code: P = IV

APPLICATION

VOLTAGES

EV HISTORY - PROFESSOR PORSCHE

The famous automotive engineer developed a way of recharging electric cars using cartridges and also built EV's with the Lohner company in 1899, selling quite a few cars before coming to the conclusion that the range with lead-acid accumulators was not that brilliant. At that point the good professor looked at putting an engine and generator set onto his electric cars to create the world's first true hybrid - and the Semper Virus was born.

SEMPER VIRUS

SOLAR POWER - Solar power is here and now. Apart from fossil fuel generated electricity, solar and wind generation will help to power Britain after the EV revolution. We would suggest that all car makers begin incorporating solar panels onto their new electric car models. The UK should also promote solar car parks and domestic car ports with solar paneled roofs - without the need to make a planning application. All such developments should become permitted developments, reference the General Permitted Development Order 2015 - that is already placing obstacles to climate change development in the paths of entrepreneurs and householders who want to help.

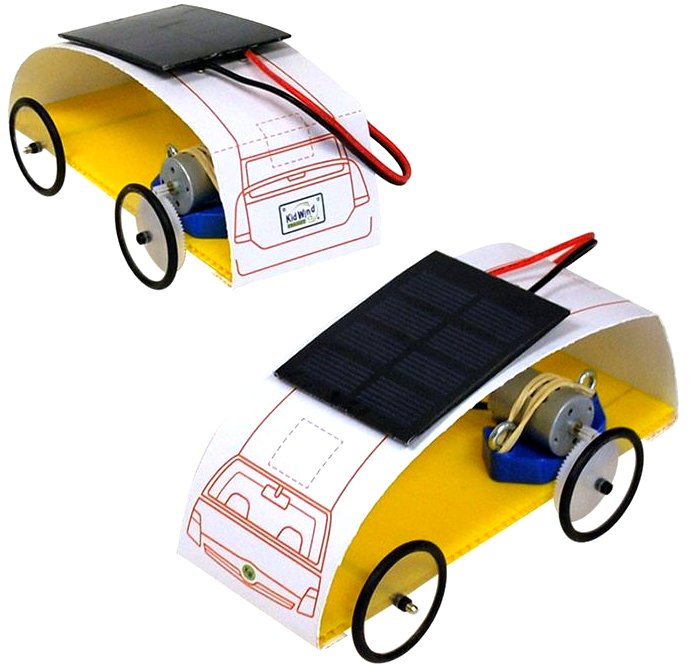

The simple model above is an educational toy. The point is that it works, it is simple and such models demonstrate that solar (assisted) vehicle can make a contribution to radical societal changes. They are of course only radical to begin with such as EVs may have been considered in the 1970s. We have passed that stage. You are no longer considered to be an eco Hippy if you drive an electric. Don't forget that politicians are not innovators, but they should encourage our technicians to think outside of the box to give them economic solutions for tomorrow's world.

PETROL TRANSPORTS

We don't want to make a big deal about the dangers of transporting flammable liquid fuels because it is something we are used to and we cannot do without petrol for our cars until there is an EV infrastructure to prevent society collapsing from fuel shortages. You probably remember the panic buying in 2012, but won't know about the fuel certificates that were issued in the 1974s ahead of oil shortages from the OPEC embargo that caused a global recession. Oil prices went from $1.80/bbl to $11.20/bbl overnight caused by the Arab/Israeli war and the world realised just how dependent on oil we are. The recession led to a three day week and food prices went crazy with supermarket shelves empty from panic buying.

We cannot let such a situation develop again by relying on imported energy. The world needs energy security and it is within our grasp. This energy will be generated locally, ending the international energy trade and giant floating oil tankers that run aground, and offshore oil wells blowing up, so leading to a more stable world.

PETROL TANKER CRASHES - Petrol tanker crashes in Lagos 2014, Melbourne 2016 and Baltimore USA 2011. It's no accident (well yes it is) that there are so many incidents, it is a statistical certainty.

CRASHES & PETROL PANIC - Petrol tanker crashes in the UK 2013 London and 2009 Peterlee, Co. Durham. Such incidents must be added to the cost of using oil for energy, added to the cost of the groundings of ships like the Exxon Valdez (1989), Torrey Canyon (1967) and the Deepwater Horizon (2010) oil rig catastrophe that cost the US $billions in cleanup and environmental damages.

CHRIS HUHNE MARCH 2011 - In a keynote speech on the impact of the oil crisis, Chris Huhne argued that an $100 (£61) a barrel price for oil would transform the economics of climate change in Britain.

PETROL PANIC 2012 - Petrol pumps ran dry with panic buying emptying stocks and stations empty with signs rationing purchases to a £10 limit. Without petrol many people could not get to work and goods deliveries would come to a halt.

ABOUT STEM & COF

STEM Learning is the largest provider of education and careers support in science, technology, engineering and mathematics (STEM). According to the Guardian newspaper, approximately 40,000 science, technology, engineering and mathematics jobs go unfilled every year. There is no way the UK can generate the number of scientists and engineers that a sustainable economy requires without tackling this problem.

One of the stumbling blocks to making engineering a career path of choice for the next generation is that it might appear less interesting to them than other professions. Our aim is to demonstrate to candidates that science can be creative and fun. It's all in the application.

PROGRESS - What would William Morris have made of the BMW i3. He'd probably have tried to buy the company. This is a great car on all roads except snow covered. The regenerative braking tends to brake the rear wheels a bit too violently causing skidding on the rear wheels, unless you ease off the accelerator very gently. That means really planning stops for roundabouts and such like with care.

LORD NUFFIELD

While we provide the project ideas, guidance and facilities, the Nuffield Foundation and STEM Sussex provide funding for students and the administration to make it happen. The decision on what projects are taken up if down to the organizers. William Morris, who later became Lord Nuffield, was a practical engineer and maker of motor cars, leaving behind a legacy to support engineering projects that might otherwise not see the light of day.

LINKS & REFERENCE

https://www.stem.org.uk/ http://www.nuffieldfoundation.org/ https://sussexstem.com/ http://www.coastalstemfest.co.uk/ https://www.brighton.ac.uk/careers/volunteering/stem-sussex/index.aspx

MARINE LIFE - This humpback whale is one example of a magnificent animal that is at the mercy of human activity on planet earth such as climate change from the burning of fossil fuels. Humans are for the most part unaware of the harm their fast-lane lifestyles are causing. We aim to change that by doing all we can to promote ocean literacy and climate awareness.

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2018. Solar Studios, BN271RF, United Kingdom. COFL is a charity without share capital. The names AmphiMax™, RiverVax™ and SeaVax™ are trade names used under license by COF in connection with their 'Feed The World' ocean cleaning sustainability campaign.

|