|

THE FOUNTAIN OF YOUTH

ABOUT - CONTACTS - DONATE - EDUCATION - FOUNDATION - POLITICS - HOME - A-Z INDEX

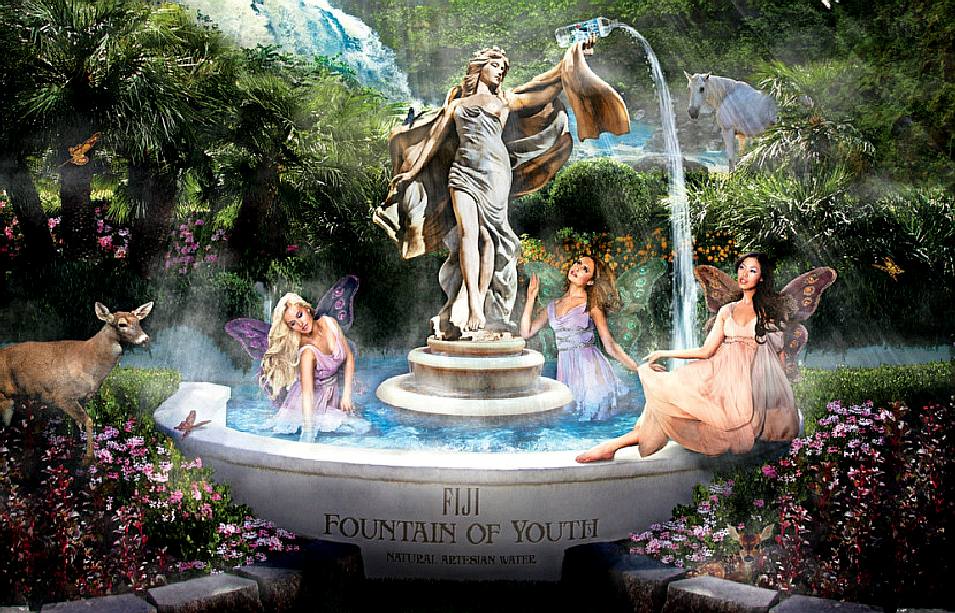

The 'Fountain of Youth' is a water feature at Solar House where a stationary (statue) version of the 'Solar (Southern) Lady' figurehead is mounted on a substantial steel reinforced brick base that doubles as a small pump house and reservoir.

Typically, works of art of this stature are cast in bronze from a mould made from a clay master. Such material would be far too heavy for the figurehead of a ship. Working in clay though, would have been a lot simpler in terms of technology and artistic alterations would have been easier to change. Then again clay has its own problems.

STUDY - This is the original sculpture that we are basing our Fountain of Youth concept on. The Solar Lady (Lady of the South - or Southern Lady) was hand carved in metal and composites, where the very first attempt was made of paper and wheat flour dough reinforced with PVA adhesive, but was all but eaten by a hungry mouse over a very cold winter, including the acrylic paint and PVA that we would have thought indigestible. This sculpture is about 300mm high.

Please note that this design is Copyright © 2010 Blueplanet Universal Holdings Ltd, with all rights reserved. This art-piece may not be reproduced as a model, statue or other artwork in any scale without the prior written permission of the company. If you wish to feature the photographs for media reviews, they must be marked as Copyright, with an attribution and a link back to this page. If these requirements are not observed, the use of any of these pictures will be seen as a breach of copyright here asserted, as defined by the Copyright, Designs and Patents Act 1988. The only exception is for educational use by teachers in schools, colleges and universities, when no permission is necessary, but a link back would be appreciated.

The Solar Lady is symbolic of life and regeneration, the relationship between air, earth and water and the cradle of life, being an angel that nurtures our hopes for the future, giving life to our next generations and looking over us, so perpetuating the youth of the human race in a continuous cycle.

In harmony with the life force that has seen us populate our glorious Blue Planet, is the desire to maintain a balance in life that mankind is prone to disregard as we use our ingenuity to harness nature in disproportion to species distribution, that prior to the Industrial Revolution and population expansion, coupled with the ease of food production and transportation that we presently enjoy, has upset yesteryear's precious equilibrium.

DURABLE - Learning from that mistake, the artist created a second carving working from the same drawings as before, but using aluminium as the former and composites that no animal would find tasty enough to want to eat. Copyright photographs © June 2013 Blueplanet Universal Holdings Ltd., all rights reserved. You will need the permission of BUH to reproduce these pictures except for educational use or media review when the appropriate credits and back links should be applied.

PLINTH - The fountain of Youth needs to be something special, even for a quiet backwater 'think-tank' in Sussex, but more to the point it has to be strong enough to cope with the loadings that will be generated in high winds. We used 100 year old bricks found on site for almost all of this pillar. Please note that these photographs of the fountain of youth and statue build are Copyright © 18 July 2017 Cleaner Ocean Foundation Ltd., all rights reserved. You will need the permission of COF to reproduce these pictures except for educational use or media review when the appropriate credits should be applied.

The study began life in 1/10th scale from sketches of birds and marine animals that were amalgamated with the human form. You can see how the concept progressed by comparing the aluminium frame above to the finished one tenth scale artwork that established copyright protection for the artist that has been donated to our charity for use with and for the SeaVax project.

Converting the beautiful lines of the original sculpture study that was hand carved from composites using knives and chisels, must incorporate load bearing mountings that were not necessary for the original that weighed less than a kilogram. In full size the sculpture will weight quite a bit more, and the wing surfaces will generate forces that the structure will transfer to the plinth that houses a pump for a fountain so that the Solar Lady is part of the Fountain of Youth water feature.

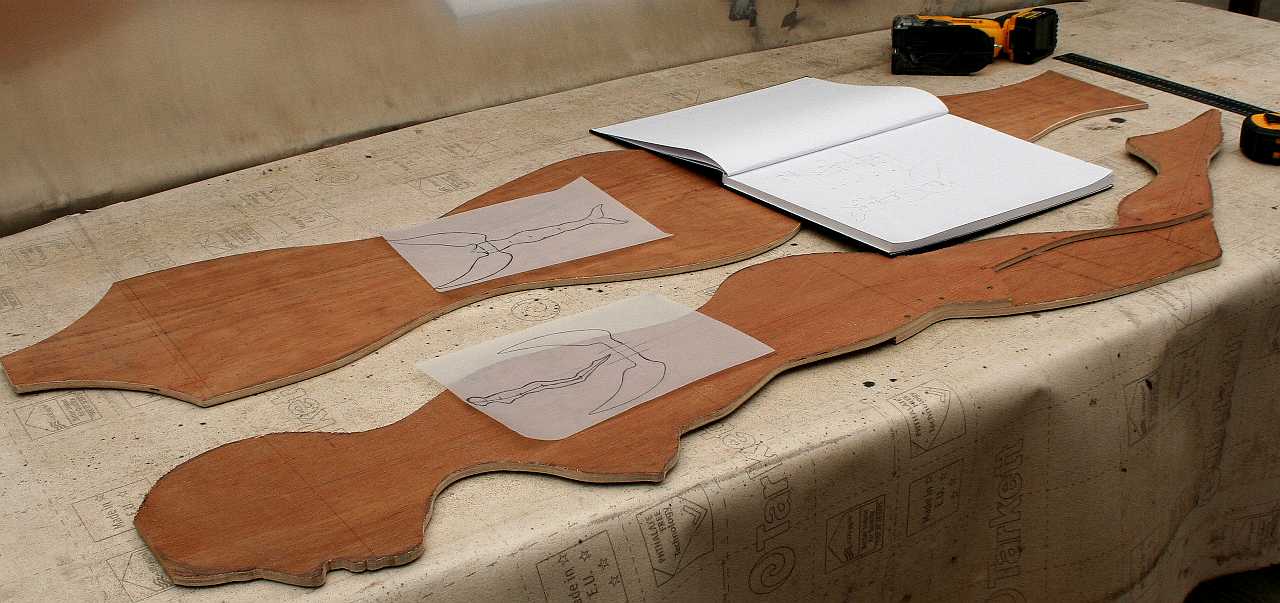

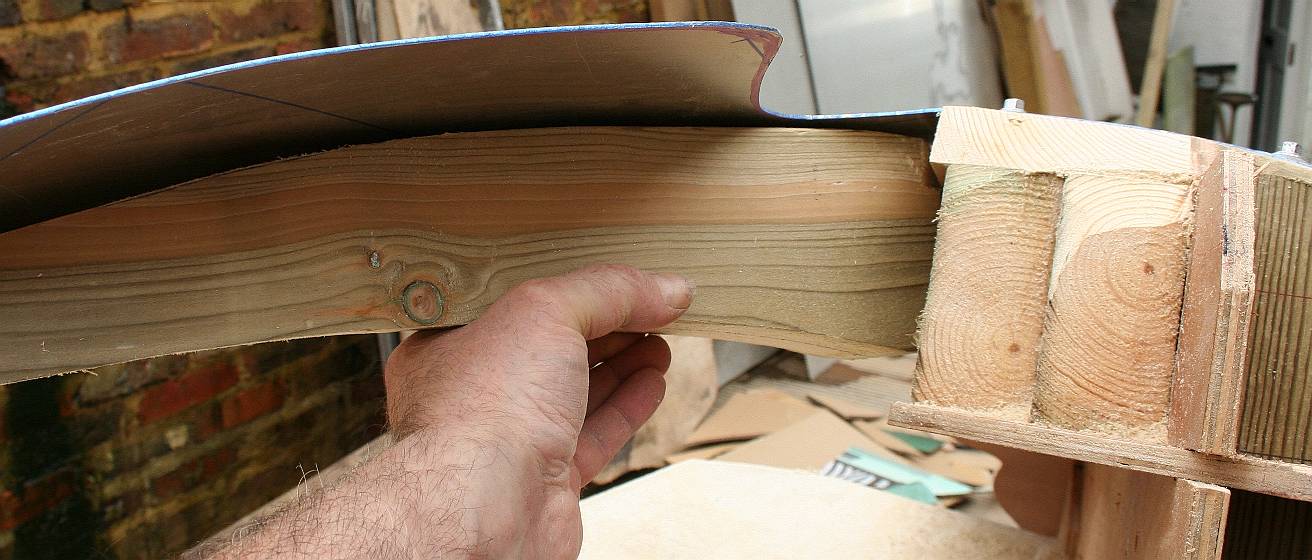

HELPER - The Easter school holidays meant a few days learning new skills in the workshops for Ryan Dusart. He is seen here holding one of the plywood formers that will piece together like a jigsaw to make a buck (wooden former) that is strong enough for the artwork that 3 meters tall to be created. The statue is to sit on top of a specially constructed brick pillar that is 2 meters from base to oyster bowl mount, meaning that the overall height of the statue will be around 5 meters or 16 feet. Copyright © photographs 4 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

FORMERS - To make a 3D sculpture you can begin with a solid block of wood or stone and carve your way to happiness, or you can make a buck from plan and side views of your sketches. This is the quickest way and more importantly; the lightest method. You will still have to sculpt the artwork from wood or whatever medium you prefer working in. We'll be using wood and polyurethane foam to get the job done in less time (hopefully). You can see one of the sketch books with the original drawings in it. This is traced to copy to another drawing that will be carefully dimensioned to loft on plywood and aluminium sheets. Copyright © photographs 5 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

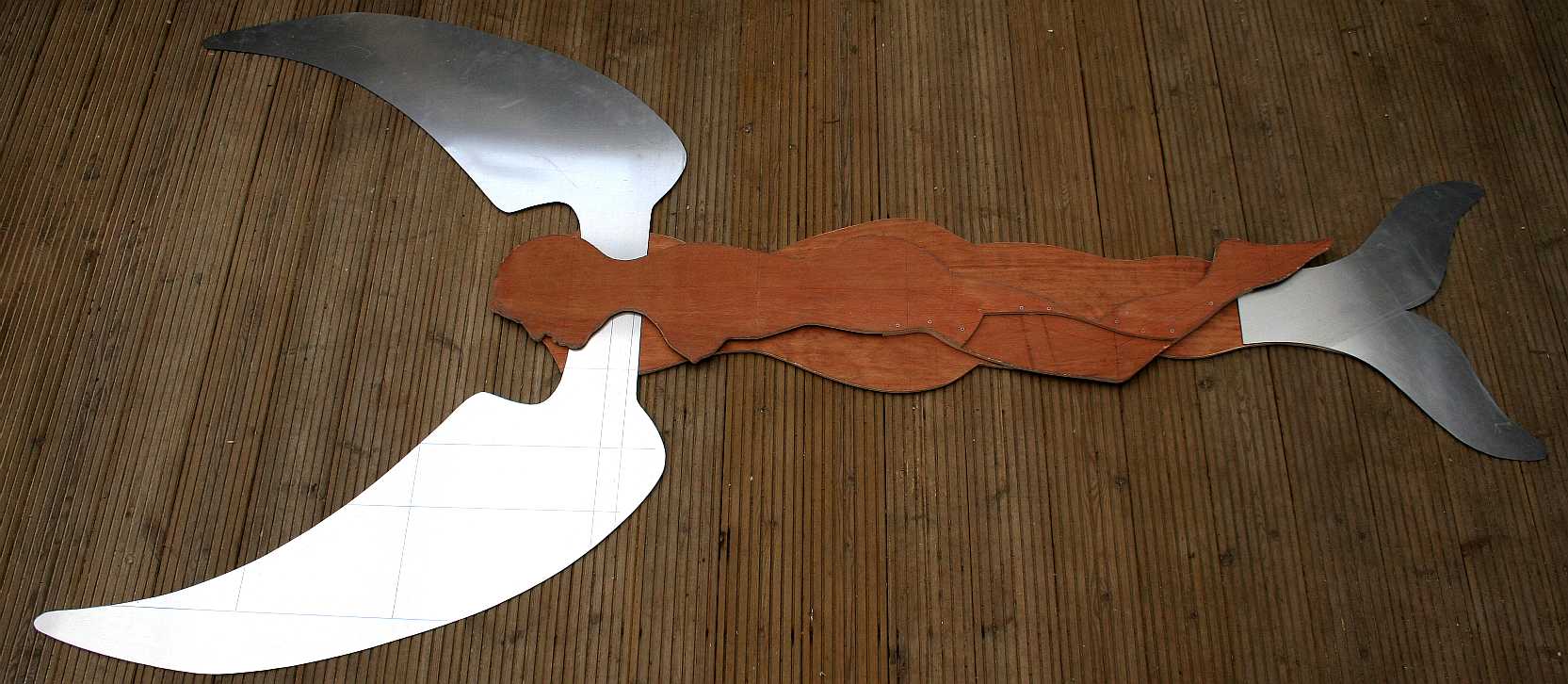

FORMERS - The aluminium wings and tail are cut from sheet metal to complete the set. Now begins the job of joining them all together. Plywood is made by bonding thin layers of wood together with the grain alternating in direction with each layer. By this means a flat board can be made that is very strong. Copyright © photographs 5 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

DETAIL CUTS - The side elevation slots onto the body plan with changes of angle that means cutting the plywood in half, being careful to mark where the structural mounting points are to be fitted. Copyright © photographs 6 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TEST FIT - Here you see a jig test-fit dry run before some minor adjustments are made ready for bonding. But, before that we need to insert some hefty wooden blocks as the mountings to carry the weight of the finished art. Copyright © photographs 6 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

The assembly is screwed together with timber to lock the templates at ninety degrees to one another . It would be a simple matter to motorize and radio control this static model. We won't have the time for that. Copyright © Jameson Hunter November 30 2018.

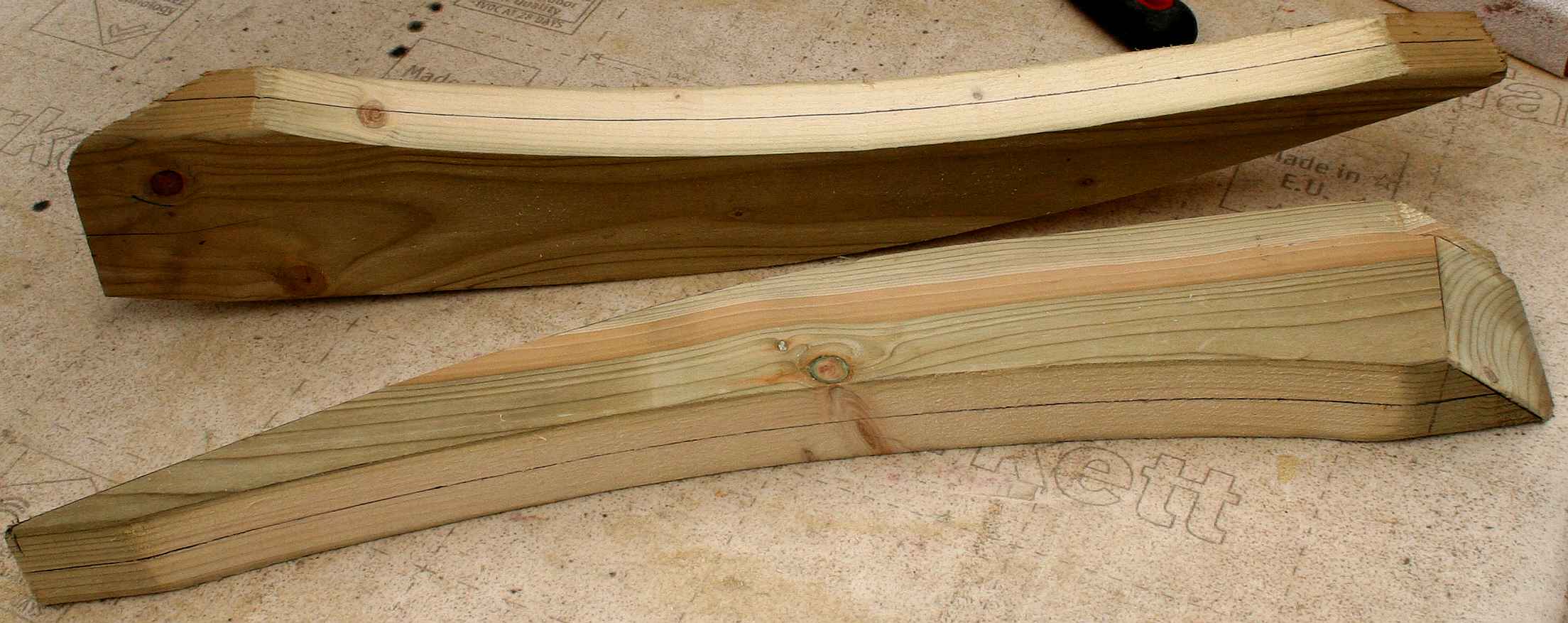

BLOCKS - We need to insert some timbers that are man enough to support the completed work of art. Wooden posts were planed to size before marking and cutting out the slots with a jigsaw. We liked the DeWalt lithium battery unit for ease of swapping blades. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

ALIGNMENT - It's worth spending a few minutes slotting the component parts together before getting out the screws and resin. Nails would also work, but screws give you more control, especially today with battery drivers. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

IT FITS - Once you are sure it all slots together as planned, mark the positions as a guide so that when bonding you don't have to line it all up again with sticky fingers. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

BORING - Having marked the blocks as accurately as you can by eye, use a pilot drill to give you the angle to follow with spade cutters. The sculptor used 22mm and 32mm cutters, coming from each side and meeting in the middle. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

ROD - If you've got it right, you can insert a mounting pole through all three blocks, in this case a stainless steel rod. As you can see, other slots in the plywood former needed to be cut to allow the steel rod to pass from one block to another. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

ANGLES - The body attitude meant that the wooden mounting blocks would be at different angles to each other. A little fettling may be need to get a really nice fit. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

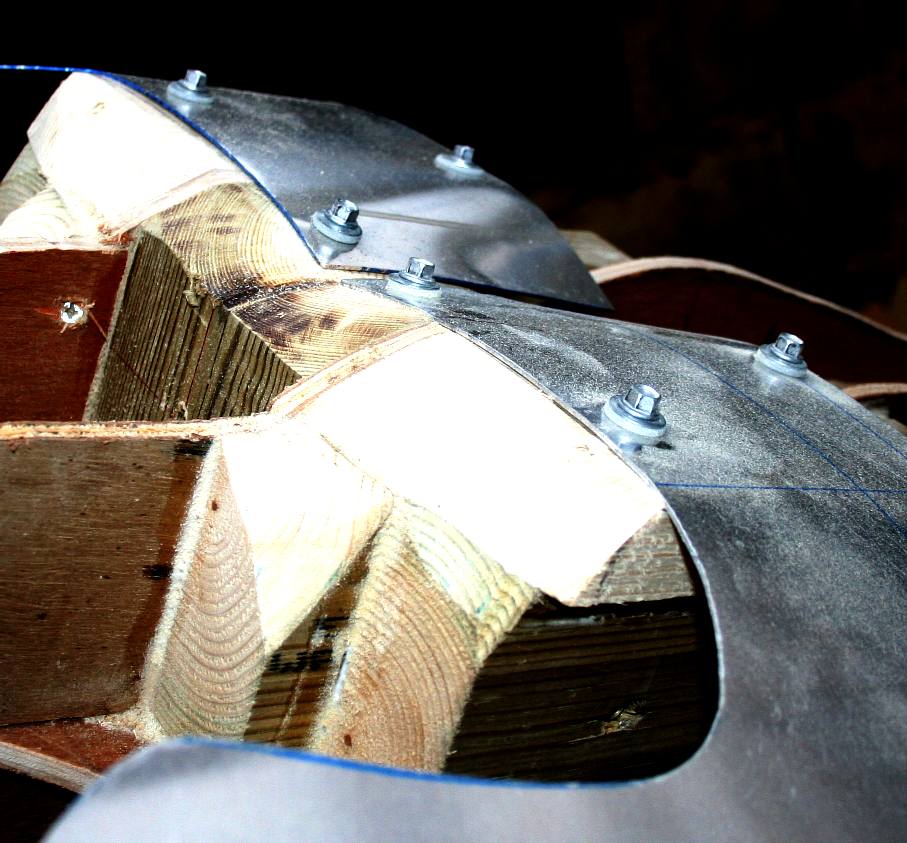

BONDING - Once the angles are marked and the artist was happy with the fit, he bonded the side formers for the back, buttocks and calves - to the blocks with a waterproof resin that is stronger than the wood. Screws are used to hold the wooden parts together while the adhesive dries. Timbers are inserted on the inside of the plywood and bonded in place to increase the strength of the frame. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

REPEAT - The whole procedure is repeated for the front, chest, abdomen and knees body former. First though, timbers are cut and inserted to reinforce the plywood, again bonded to the wooden panels to increase the strength. The alternative to this method is to bond a series of solid wooden blocks together and carve the figure with sharp chisels. As this is a scale up of an existing artwork, the former method more accurately reproduces the outline. The artist still has to carve the finished piece by eye, but has datum points as a reliable reference. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

FRAME - Another view of the timber frame. It is important to cut inserts accurately to make a wooden beam from one mounting point to another. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TAIL - The Mermaid tail is slotted into place for a dry test fit. The wings are much larger. They will need reinforcing with timber and steel because they are thinner. Once the body is carved, the whole assembly will be sheathed in carbon fibre before being final shaping. After that gold leaf will be applied. Copyright © photographs 7 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

CHEST - Wooden blocks are cut and fitted to strengthen where the wings of this southern angel will be attached. Copyright © photographs 9 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

SHOULDER PADS - Pads are bonded in place to mount the wings of the angel. These pads have to be curved to match the profile of the wings as they arch into the spine to create a distinctive back. Copyright © photographs 9 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

BOLTS - The wings are bolted in place temporarily so that shaping of the shoulders and neck can begin. These bolts will be removed and replaced with countersunk screws once the wing panels are more securely attached. Copyright © photographs 9 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

LITTLE & LARGE - The original art piece is compared to the statue during the making. The large aluminium wings will need reinforcing with shaped timbers and then a second skin on the inside of the curve, where the wing will attach to the underside of the shoulder blade. Copyright © photographs 9 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TAKING SHAPE - The Fountain of Youth statue is beginning to look like the original angelic sculpture at the head of this page. There is still a lot of infill needed and the actual head frame to attach, where that seen so far is only there as a guide. The sculpture manages to capture both the swimming action of a mermaid and the flight of an angel in one mythical creature. Copyright © photographs 9 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

ANGEL WINGS - The aluminium wing templates are seen here unsupported and vulnerable to damage in the studio unless reinforcing spars are inserted. You can see the first spar on the table. Copyright © photographs 10 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

DETAILS - [LEFT] The shoulder joint is seen here with the angles cut so that the aluminium wing blade sits correctly. The process of getting this joint right is largely trial and error. It's better to take off too little than make a mistake and cut off too much. [RIGHT] Cardboard (or paper) can be used to work out the flat sheet development of a reinforcing bracket that will also be made in folded then beaten aluminium. The metal article will not be as compliant as cardboard. Copyright © photographs 10 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

MIRROR IMAGE - The two arms that reinforce the wings are seen here marked with centre lines so that when the wings are drilled to screw to the timbers there are reliable guides. The bones of birds are hollow to keep them light and dense only at load input areas such as where the muscles attach and at joints. Weight is a consideration for us where the statue is used as a figurehead on SeaVax. This first sculpture will be used as a statue on the Fountain of Youth. Copyright © photographs 10 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

PROFILE - The curve in the wooden supports matches the wing profile as near exactly as possible by human eye and measurement with tapes and rulers. We don't need to be too fussy because minor irregularities will come out at the carving stage. Copyright © photographs 10 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TIGHT FIT - When making custom artworks it is not always possible to get a 100% fit as in furniture that is machine made - and it is not practical to keep re-making the same item. Hence, when designing the support structure make sure that it will be strong enough with suitable fixings. Triangulations is the key and this joint is a good fit. Copyright © photographs 10 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

DEWALT - The artist seems to use a lot of lithium battery tools to aid in the creative process and likes this brand. In this picture you can see both wing arms fitted. Once the shoulder brackets are fixed it will be time to get out the resin and glass matt. Lloyds approved marine ADX40 resin is used for the reinforcing, where carbon fibre and epoxy resin will be used on the figurehead for the outer skin. Copyright © photographs 10 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

FOLDING - You need a good eye and some skill with basic tools such as flat nosed pliers. You also need a hammer or two with smooth (polished) heads. One hammer in use (a Stanley) is over 50 years old. Copyright © photographs 11 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

FIXED - Screwed down and beaten to fit the wooden arm. Most of our fixings come from Screwfix in Hailsham and Eastbourne. The craftsman used ordinary pop rivets to join alloy to alloy. These need to be hand beaten for a tighter fix. Special countersunk rivets are available for a flush fit. Copyright © photographs 11 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

REPEATED - The left and right brackets should end up virtual mirror images, meaning that the folds are reversed. It is impossible to fit a straight folded section to a curved wing, you need to fan and fold each tab to fit the curve one-by-one. The same techniques used to make the Solar Lady can be applied to make giant animatronics, such as dinosaurs and sharks, except that the joints would be mobile, hence timber would be replaced with steel and adhesive with welding. Our artist is also a skilled welder-fabricator - so could have made the wings work if that had been a requirement. As a water feature that would not be appropriate. Copyright © photographs 11 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

KNEES - The tail does not need to carry any structural loads, but you can imagine that during transit and fitting that the installers will lift by the most convenient handholds - and these will be the wing ends and tail tips. Hence, even the extremities need to be able to take reasonable loads that pass through the knee joint. In a sold bronze casting that is not usually the case, the metal being more than able to cope without complex structural considerations. Copyright © photographs 11 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

COMPOUND CURVES - Forming metal skillfully can take a flat plate and breathe life into it with curves in all the right places. When beating sheet metal, be careful not to ruck the metal with high stress creases - or at least beat those out. Our artist makes a mental note of potential problems to deal with at each stage, before proceeding to the next stage. Copyright © photographs 12 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TOOLS - From the most basic of tools you can produce some incredible artwork. For example, a master painter like Leonardo da Vinci only needed a few brushes, some oils and a canvas to produce the Mona Lisa. The end result can be stunning, in Leonardo's case becoming a national treasure. Copyright © photographs 12 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

METAL FORMING - Some of the most exclusive sports cars were made in aluminium where craftsmen rolled metal by hand using the eye to make the panels for exotic bodies. Typically, such craftsmen worked to a pattern of the vehicle they were producing made in wood called a buck. Copyright © photographs 12 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

CURVACEOUS - Metal that is curved is far stronger that flat sheets that would need reinforcing. Working metal also hardens it. So start with a suitably soft (annealed) grade. If you work-harden metal too much it will crack and you'll have to start all over again, or anneal and repair. Our artist got nowhere near causing fatigue during this creative exercise. Copyright © photographs 12 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

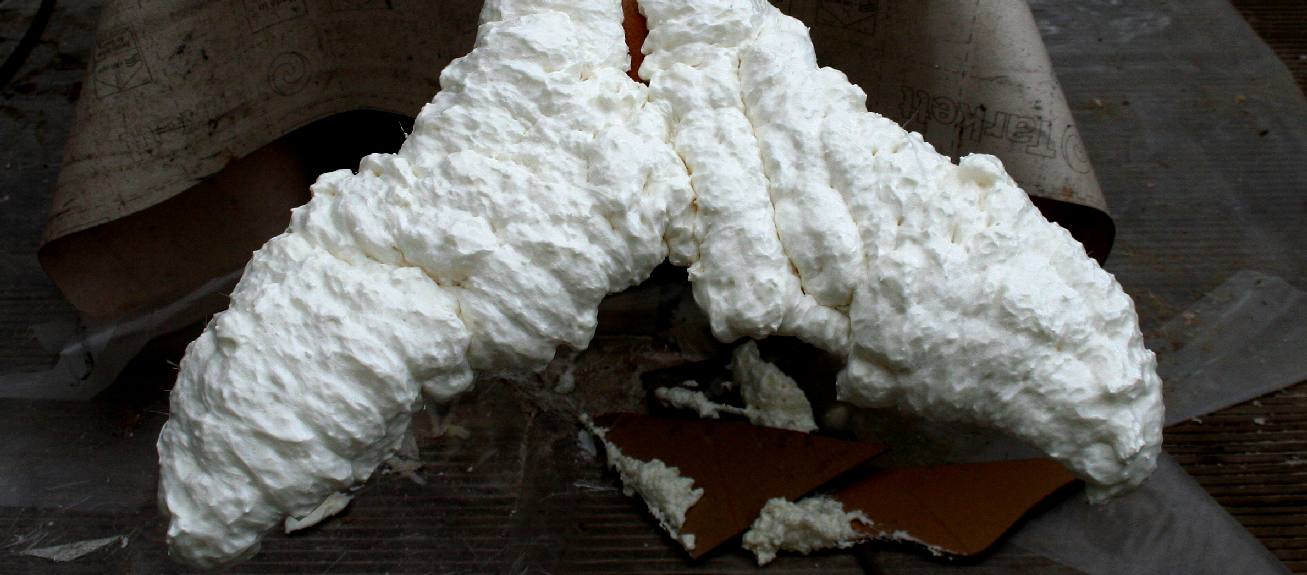

CORE - In the modern world, where we are creating a dynamic artwork like a figurehead, we can take advantage of materials like polyurethane foam. They not only speeds up the carving process, but will leave us with a piece that can withstand substantial loads on a vehicle at sea in harsh weather conditions. That is why ship mascots were hewn from solid blocks of wood. Wood being lighter and stronger than stone or bronze and still strong.

The carving process is just as intricate using foam as a core material, with the problem that with speed and ease of working, you have to be more controlled and the slightest slip will undermine the artwork a whole lot more than carving marble or wood with a chisel. It is easier to make a mistake, but unlike stone masons, if you make a mistake it can be rectified with a fresh application of polyurethane. The core material will be sheathed is a composite that is far more durable. It is important to get the shaping right at this stage so that the laminating process does not need to involve form adjustment. The foam is applied from canisters and must bond to clean dust free surfaces. Each section has to harden before the next application, so be patient. Copyright © photographs 12 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

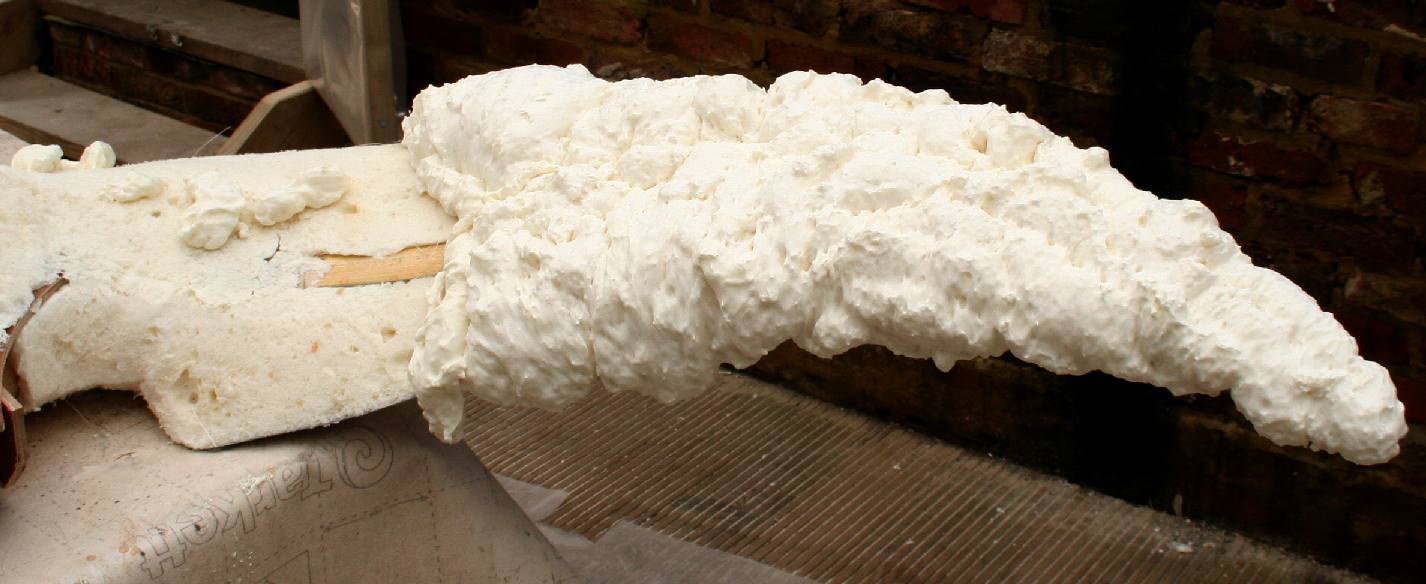

ROUGH SHAPING - The polyurethane foam can be rough cut with ordinary saws, being careful not to tear the material. The process must be repeated several times as each facet is built up. Finally, each completed section should be laminated with a high grade epoxy and suitable woven rovings. The static version will still use epoxy resin for final lamination, but polyester and vinylester resins for local structural reinforcing. Copyright © photographs 14 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

INTERIM SHAPING - The second stage is to shape the foam to a point where a laminate can fix and preserve the form for final detailing. This has to be as near to the finished art as possible, allowing only another millimeters or two of material to complete. Copyright © photographs 14 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

MERMAID TAIL - Where the aluminium fins meet the wooden structure, the artist has included several layers of chopped strand matt at the join, that will be built on with foam and layered over with epoxy and a woven glass cloth for the final form. Any metal that is being laminated must be properly keyed for a good bond. Copyright © photographs 14 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TAIL REVERSED - The underside of the mermaid tail is reinforced with GRP to create a composite sandwich that is very strong. This will be filled with polyurethane foam and shaped to form a core, when the whole tail is encapsulated in a skin of epoxy resin and woven glass cloth for the statue, or carbon fibre for the figurehead - before being gilded. Copyright © photographs 15 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

CORE FILLING - The underside of the tail is seen here filled or covered with foam. In about 12 hours the foam will be cured sufficiently to carve to shape. See what that looks like below. Copyright © photographs 15 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

ROUGH & SMOOTH - The underside is carved in principle while the topside receives a first coating of polyurethane foam that also has to be shaped. It is only possible to do one side at a time unless a temporary stand is made, but even then the top half would have been hard to reach. Some features need two coats of foam to build up sufficiently to then carve. The head will need several coats of foam, even with formers. Copyright © photographs 15 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

MUMMY - The core foam is applied to the wings and shoulders, making the art piece look like something out of a Mummy film. Apart from the art and sculpting elements, the skills used to create this statue are much the same as for boatbuilding. Copyright © photographs 15 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

ANGELIC - Seen from a distance, the angel form is still apparent even when liberally covered in polyurethane foam. The foam can either be mixed in a container or applied from a can using a trigger valve. The wing tips still need reinforcing with polyester resin and glass matt (fiberglass), or maybe the artists will go for epoxy resin at this stage. We are expecting a large consignment of resins and cloths this week. Copyright © photographs 15 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

SOUTHERN ANGEL - From the cured foam our artist rough shaped the ocean angel. Copyright © photographs 16 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

FORM - In this picture you can see the figurehead emerge from the block of foam. There is still a way to go where, after the 2nd stage detail is carved, this has to be locked solid using epoxy resin and woven glass cloth. The next step is to reinforce the angel's wing tips with several layers of fibreglass matt, followed by a polyurethane core and epoxy resin sealing. The 3rd stage detailing is just as time consuming using epoxy putty to fill any blemishes prior to surface preparations and a coat of 2-pack varnish ready for gilding. Copyright © photographs 16 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TAIL FLUKES - Here you can see the mermaid tail fins shaped in foam, with some infill of large hollows created as bubbles during the curing process. Copyright © photographs 17 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

PREPARATION - Before any laminating session, no matter how big or small the job, it is wise to set things out ready to place on the artwork. This is because the working time (pot life) of most resins is about 20 - 60 minutes. Using fast cure resin as in this case for small wing sections, the resin starts to glob after 10-15 minutes. You have to get a move on - and switch off your mobiles. You can see here that the resin in measured out and the chopped strand glass matting is torn into sections to be placed around the wing edges. It is better to tear rather than cut for this exercise. Copyright © photographs 17 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TIPS - This is one of the wing tips after lamination. The centre of the wing has fewer layers of glass matt. Trim the edges while still soft, or grind off the excess when cured. Wash all mixing pots, brushes and hands in acetone. Cellulose thinners is also useful for cleaning, but takes the oil out of your skin, so wash as infrequently as you need, or allow time for the hands to regenerate between laminating bouts. Copyright © photographs 17 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

FOAMING - The polyurethane foam is applied to cover the fibreglass. Make sure of a good bond by dampening the surface. This helps the foam adhere to any surface and cure. Once shaped the wing can be sealed and further strengthened with a skin of epoxy resin laminate. If you are on a tight budget and weight is not so critical, you could use chopped strand glass matt and polyester resin. This is glass and glass is dangerous if it pierces your skin. So wear gloves if you can and a mask while sanding and the like. Copyright © photographs 17 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

WINGED - The foam is shaped and prepped ready to be coated in epoxy resin then laminated with two layers of glass fibre cloth. This is how they make surfboards and the laminating system is more or less the same. Copyright © photographs 19 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TAILFIN - Two layers of woven glass fibre cloth are cut to size for the mermaid tail fin. Copyright © photographs 19 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

WINGS - Two layers of woven roving are cut for each wing with overlaps that will be folded under the wing where possible for extra strength. Sometimes the flaps will not stay if there are irregularities on the undersurface, so prepare well. Any folds that do not work on the front of the wings will be caught when the back of the wing is laminated. Copyright © photographs 19 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

WINGS - The upper (outer) wing surface is next for a coat of epoxy and woven glass cloth. The rivets and wood screws are ground down and the aluminium must be keyed for a good bond. The artist is at this stage working on the head drawings and considering the best angle where the statue is mounted at a different angle to a figurehead. Copyright © photographs 23 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

TAILFINS - The feet and tail need a bit more shaping before the back can be laminated with epoxy resin and glass cloth. After that the body needs final shaping before that too is preserved with a layer of resin and glass. Copyright © photographs 23 April 2018 Cleaner Ocean Foundation Ltd. All rights reserved.

FACE OF AN ANGEL - Who or what will the face of this angel look like? At the moment the artist is considering how to treat the face.

FOUNTAIN OF YOUTH - There are water fountains all over the world. Some explorers have devoted their lived to finding mythical waters that are supposed to imbue those who drink from them with longer lives. One of the secrets to a long and happy life is to stay active and exercise daily. Another tip is to eat healthy food and not too much.

This website is provided on a free basis as a public information service. copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2018. Solar Studios, BN271RF, United Kingdom. COFL is a charity without share capital.

|