|

1st YEAR - SCALE TESTS 10 YEAR PLAN

ABOUT - CONTACTS - DONATE - FOUNDATION - HOME - A-Z INDEX

OCEAN CLEANER - SeaVax is designed to operate in fleets. The development stages are costed below as estimates that the Cleaner Ocean Foundation is looking to world leaders to fund, while the cost of the ocean cleaning fleets is to be shared across operators world wide - and so is not included, save for the licensing and fleet negotiations. Fleet operators will recover their investment from collected plastic, with a possible guarantee from the countries in which they are operating. All subject to negotiation. Without such an approach, COF feel that it would be difficult to roll operations out, save perhaps for underpinning from international organizations. This part of the plan falls to be considered in year 8.

THEORY PROVING (SCALE) TANK TESTS

This stage involves testing of a number of engineering models, together with plastic filtration experiments in our rapid flush (dual) test tanks using full size engineering modules where practical.

Scientific test equipment is to be installed in our dedicated marine biology laboratory that has been set aside on-site adjacent to the test tank and SeaVax workshops for biological analysis of the tank experiments, to include: simulating seawater treatment loaded with (filtration stage 3) biota, to compile separation data for year 4 project development.

Water in the test tank will be charged with plastic particles and the appropriate biota to simulate the soup found in the gyres in the Atlantic, Indian and Pacific oceans. Various filtration methods will be tested, with the exit fluid tested for plastic and marine life content. The ideal being that the plastic is removed with the marine life remaining in the water unaffected.

FACILITY LAYOUT - Diagram of the general layout of the COF's facilities in Sussex. One of the most important features of the water test tank is the underground holding tank that allows us to drain the test tank completely and filter the water with each flush into the holding tank. The test tank is then filled again with filtered water from the holding tank, ready to be charged with plastic particles, marine biota or a mix of both. The object being to find the best way of separating inanimate plastics from organics, to preserve life. The whole operation takes less than 60 minutes, meaning that two or more experiments may be conducted every day, save where a machinery change is also necessary.

In addition to these facilities there are two workshops where heavier fabrication work may be undertaken, such as the build of the filtration modules, conveniently and close to the test facilities.

The objective of these experiments is to identify the most efficient way of separating micro organisms from micro plastic as the 3rd stage of SeaVax filtration. Though SeaVax is a versatile platform that will be able to collect macro plastic using less sophisticated selective particle separation in the equation, we consider that it is worthwhile investigating this optional module such as to be able to clean the garbage patches of micro plastic particles, leaving the marine life in a cleaner environment. As far as we are aware we are the only organisation currently active in this area of ocean research.

The equipment that is needed to conduct these tests is moderately priced. Where our facilities are located conveniently to one another and we have a fast-flush system to discharge and recharge our test tank, we might complete a series of separation tests in a shorter timeframe and more economically than if using outside facilities that are geographically logistically challenging.

The diagram above shows the layout of our facilities. This diagram does not include our other workshops where heavier engineering may be completed, such as fabricating the filtration modules, ready for assessment in our test tank. These facilities are also within the same complex.

MICRO PLASTIC FILTRATION

More of a robotics challenge coupled with sensors and end effectors than stages one and two, it is necessary to be able to differentiate between micro plastic and small marine organisms as the key to engaging the appropriate settings of the mechanical components of the onboard filtration equipment.

There are several ways of identifying objects in the seawater using underwater cameras, sonar and other sensors, where the potential harvestable area ahead of a SeaVax vessel is read as the vessel navigates the oceans, which live input is then analyzed by computer algorithms against a recognition data base that is created from studies of plankton, zooplankton and other marine life. The real-time information is used to tune the onboard equipment for maximum collection, while at the same time protecting the biota element from accidental harvesting.

COLLABORATION

We are looking for collaborative partners in connection with grant applications from European member states and other third party countries in the following robotics and communications areas:

* Autonomous energy harvesting * Blue water transfers between unmanned (and manned) vessels * Computer programming * Cameras * Earth observation * Mechanical handling * Remote fleet control * Remote human interfaces or drone control * Robotics * Sensors * Sonar

* Geodata dissemination

10 YEAR PLAN: PROJECTIONS AS DEVELOPMENT MILESTONES Vs PROJECT COST IN $MILLIONS

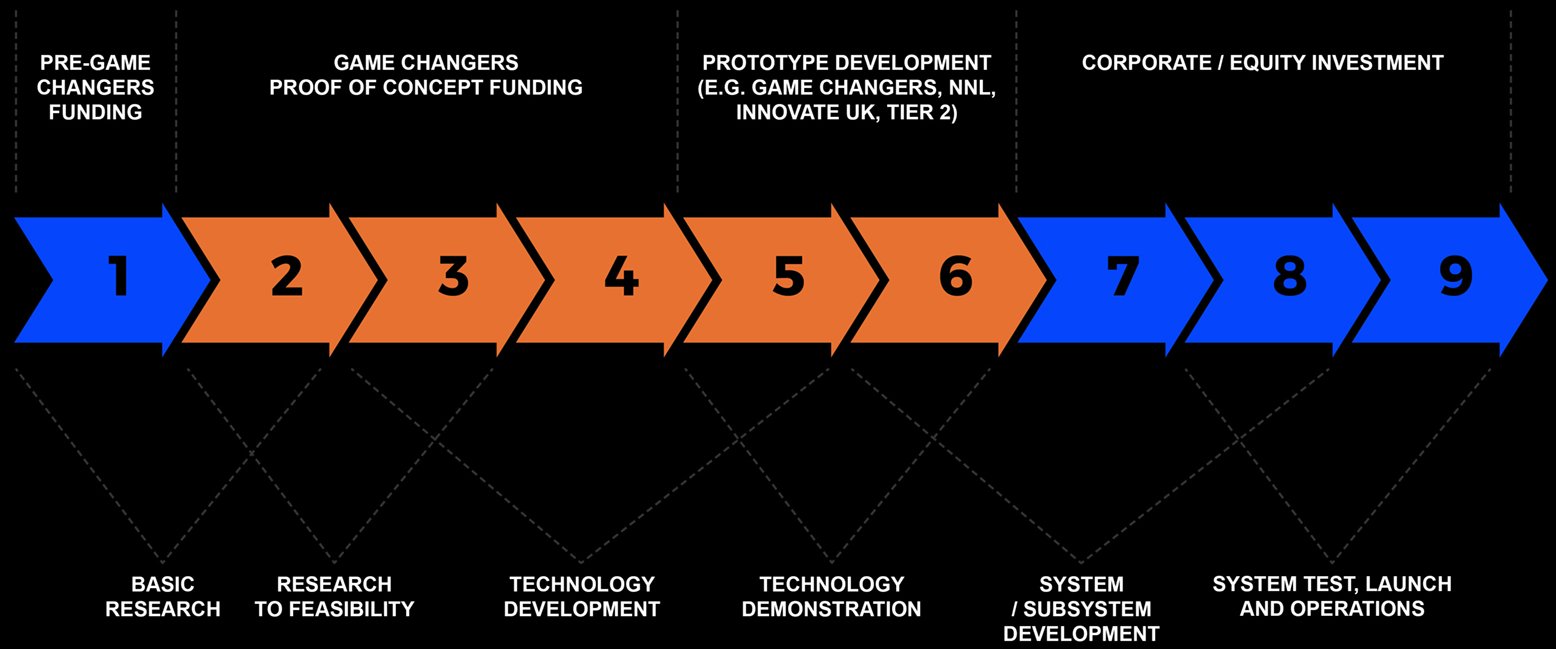

TRL 1 - TRL 2 - TRL 3 - TRL 4 - TRL 5 - TRL 6 - TRL 7 - TRL 8 - TRL 9 - TRL 10

TRL SCALE - The TRL scale is a metric for describing the maturity of a technology. The acronym stands for Technology Readiness Level. The scale consists of 9 levels. Each level characterises the progress in the development of a technology, from the idea (level 1) to the full deployment of the product in the marketplace after level 9. *The timescale is funding dependent and for that reason may be subject to a multiplication factor of 2 or more in terms of technology readiness, to become a 20 or even 30 Year Plan, meaning that by 2050 there is likely to be more plastic in our oceans than fish.

TEN YEAR PLAN: 2020 - 2030

The ten year plan is to run from funding agreements that must demonstrate a necessary level of commitment from those participating in the World Ocean Antiplastic Alliance or other funding partners, by way of an incentive to complete the above stages of the project as proposed, or as subsequently amended and agreed following the results of each work package.

SUPPORT OUR RESEARCH

Please help us if you can by making a donation of any size to help us to be able to share our research with the world. At the time of publication of this page we are not supported by any government or agency. We are reliant on help from members of the public who care about marine conservation. Though in the fullness of time we hope to be able to interest international groups who might agree that collaboration is necessary if we are to rid the oceans of the plastic menace.

SHOP CLEAN

Please also try not to buy products in single use packaging and if the opportunity presents, lobby your political representatives to help reduce plastic used on land from entering our oceans.

Plastic is a wonderful product that is necessary in modern life and it can be recycled responsibly such as not to harm fish and marine mammals. For example, many car and computer parts are now designed for recycling. Plastic is not all bad. Many manufacturers now think Circular Economy, introducing sustainable practices and crucially, many supermarkets that are reliant (for the moment) on single use plastic to sell their wares, are giving the plastic issue a good deal of attention.

We offer big THANKS to all concerns who are working to a cleaner end.

WORLD OCEAN ANTI PLASTIC ALLIANCE (WOAA)

Those with the ability to put the matter right, owe it to those who do not, to act positively to protect their neighbor's interests regardless of political differences. If that means assisting countries around the world to recognise the problems on their coasts, then that is one of the targets. For, if enough Governments join forces anything is possible, especially with potential solutions like SeaVax on the horizon - where in order to make such a system work we need global coordination and collaboration working independently on this one issue as brothers united in the war on plastic. The G20 are committed to reducing ocean pollution - at the moment limited to land based sanctions.

We don't expect every G20 country will agree to joining the Anti-Plastic Alliance, we just hope that those who are inquisitive and open minded will find it in their hearts to set aside a small budget for blue-sky research. Such generosity could part sponsor our efforts, thus reducing the burden on other non-G20 countries who depend on fish and fishing as part of their economy and maritime heritage.

LINKS & REFERENCE

http://www.

MARINE LIFE - This humpback whale is one example of a magnificent animal that is at the mercy of human activity. Humans are for the most part unaware of the harm their fast-lane lifestyles are causing. We aim to change that by doing all we can to promote ocean literacy.

This website is provided on a free basis as a public information service. Copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2018. Solar Studios, BN271RF, United Kingdom. COFL is a charity without share capital. The names Amphimax™ RiverVax™ and SeaVax™ are trademarks.

|